The future is here NOPA Engineering

NOPA Industriearmaturen GmbH

ENGINEERING

Strong solutions from one source, adapted to your needs down to the smallest detail and significantly improving your plant availability – this is what the name NOPA Industriearmaturen stands for. Every day, our engineering engineers work to develop solutions for you that are optimally designed for the application, whether in economic, ecological or technical terms.

NOPA Industriearmaturen GmbH

Project Development

NOPA sees itself as a valve general contractor who supports you throughout the entire life cycle of the valve. From the initial idea and basic engineering, through detailed planning and design, to installation and commissioning. But even then we don’t stop there, because we continue to support our valves even after commissioning as part of regular inspections and maintenance work. Crucial for you: we offer the all-round carefree package so that you can concentrate fully on your core business.

This is how

unique solutions

Customized industrial solutions

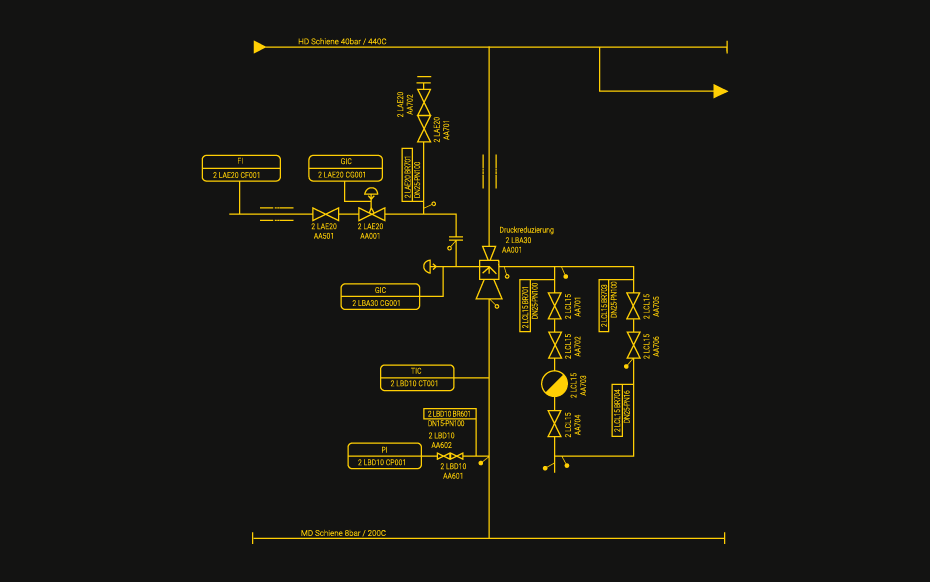

What we can do for you

Our engineers develop, plan and design solutions for you that will take your operation to a new level. A close exchange and detailed coordination with our customers are particularly important to us in order to understand and precisely implement their requirements. Using the latest software and technology, our engineers work out different alternatives and create suitable product configurations. We never take a one-dimensional view of your project, but always look at it from all perspectives. The result is the optimal combination of:

Economic efficiency

Durability

Performance

Sustainability

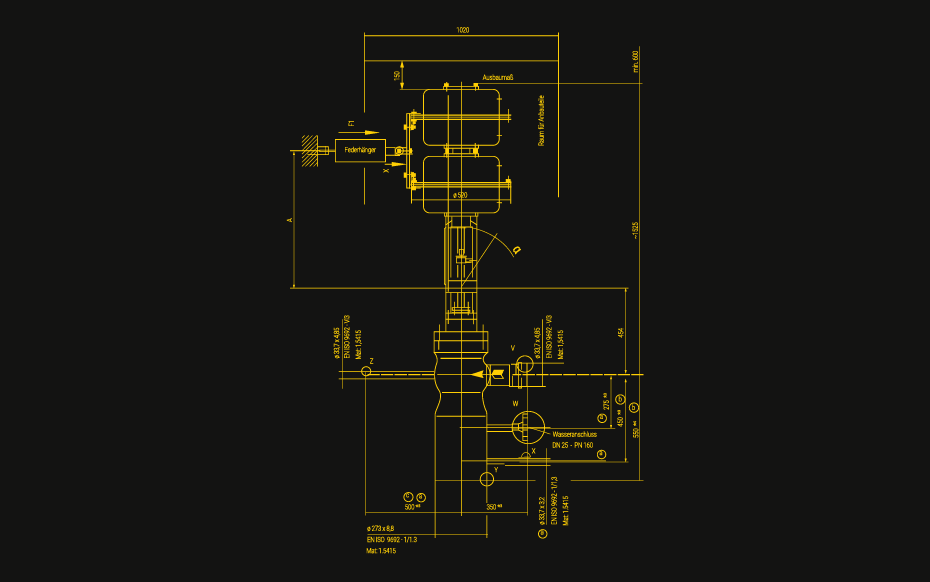

Based on our many years of experience, we can design a wide variety of systems and optimize them in terms of flow and wear, whether control valves, differential pressure sensors, bursting discs, safety valves, heat exchangers or pumps. Piping calculations are also part of the services of our engineering team.

Your path to a sustainable future

Resource efficiency

Today, no company can ignore the issue of sustainability. Being resource-efficient and environmentally friendly is one of the most important cornerstones of our services. Together, we work to reduce your operating costs while minimizing your energy consumption and co2 emissions.

- Potential analysis

Find out which parts of your operation we can make more sustainable with efficient special solutions. - Process optimization

In line with your individual goals, we design economical and modern processes that enable you to achieve more at lower cost. - Method optimization

Thanks to method optimization, you gain reliable processes and minimize your downtimes.

Why nopa?

Your advantages

- State-of-the-art analysis methods to reduce operating costs

- Minimize energy consumption and reduce co2 emissions

- Highest possible plant efficiency and minimum downtime

- Optimized product selection for maximum plant availability

- Preventive maintenance for optimally working valves

- Service webapp