Steam forming stations PM2

“Hamburger Rieger”

NOPA’s project at Hamburger Rieger GmbH Papierfabrik Spremberg, carried out between July 2019 and February 2021, focused on the development and implementation of steam forming stations. With a focus on reliability and customized solutions, this documentation illustrates the technical and collaborative aspects of the project.

Client: Hamburger Rieger GmbH Papierfabrik Spremberg

Project period: 2019 – 2021

Location: Schwarze-Pumpe PM2

Special features:

- Customised engineering

- Security-focussed

- Complex implementation

- Efficient system performance

Contact person NOPA:

Rene Baeske

Innovative engineering

for Hamburger Rieger

NOPA was significantly involved in the construction of the PM2 paper machine for Hamburger Rieger GmbH on site Schwarze Pumpe. The task included the engineering of the steam control and forming stations for the LEAG emergency supply and the PM2 steam supply.

The client’s focus in this regard was on high operational reliability, standardization and ease of maintenance. This included the whole execution planning and product engineering, with NOPA focusing on durable, innovative solutions that were precisely tailored to customer requirements.

Planning of steam forming stations

Development and selection of customized solutions

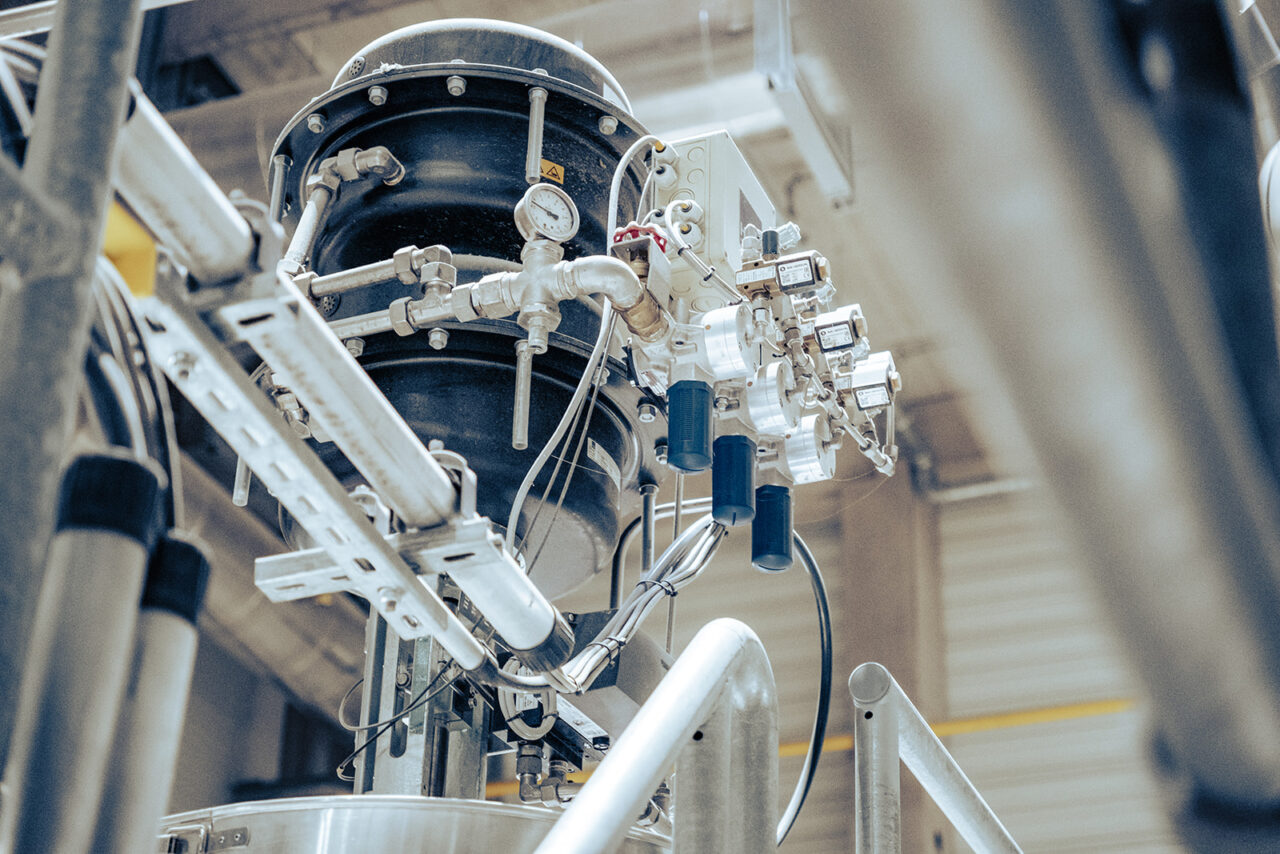

Based on the process engineering requirements, NOPA created the complete design and detailed planning, including the product specification for the entire steam control lines, while complying with all safety requirements. NOPA worked closely with the project engineers, plant managers and the responsible TÜV (Technical Supervisory Association) experts.

Implementation at Hamburger Rieger

Partnership-based implementation and technical expertise

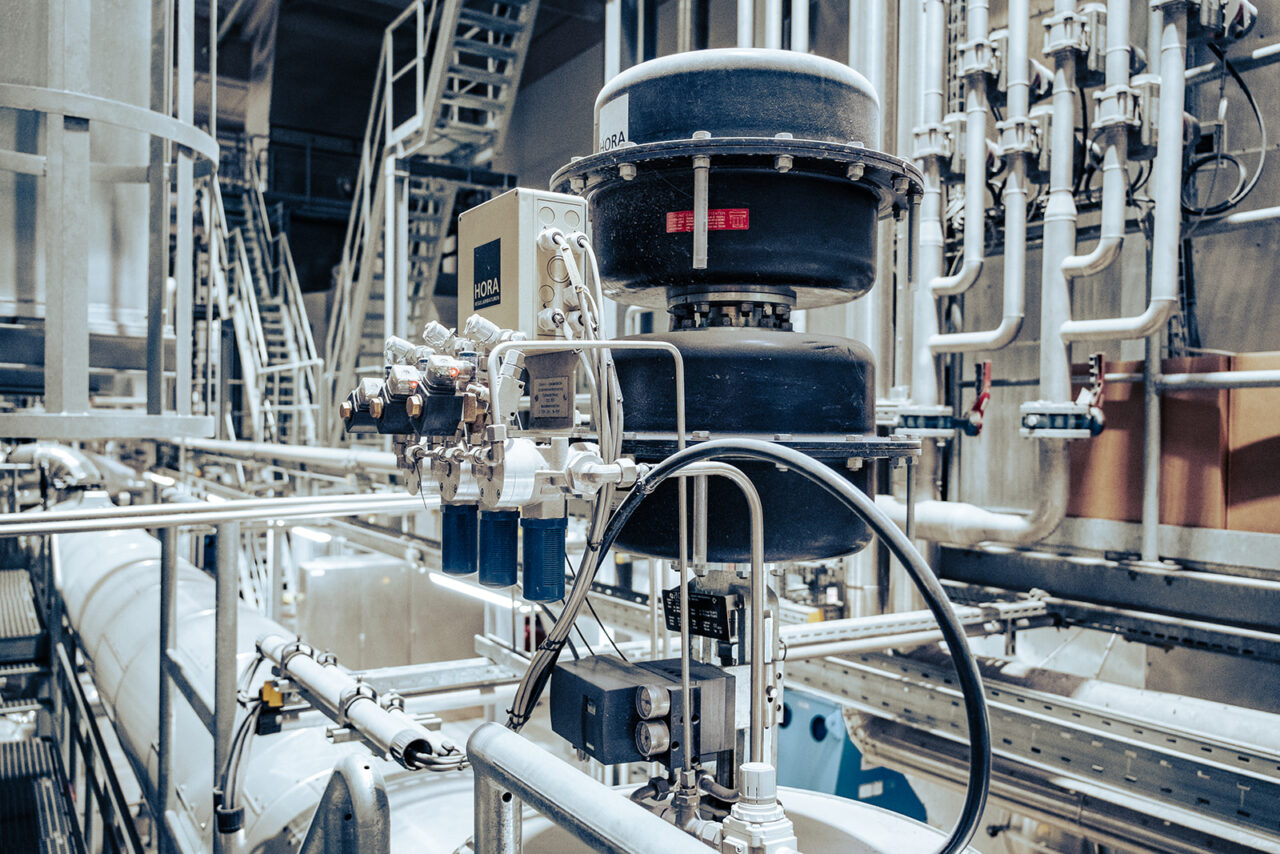

During the implementation phase, NOPA acted as a full-service contractor and technology partner for the Spremberg paper mill. In construction phase 1, the focus was on dismantling the old systems and setting up the LEAG emergency supply, including the full commissioning of the steam control system. In construction phase 2, NOPA supplied the components for the entire steam control system of the newly constructed PM2.

In close cooperation with the client and TÜV (Technical Supervisory Association) experts, NOPA ensured that all components – from steam converting valves to safety devices and safety valves – met the client’s high requirements for operational safety and could be put into operation without any problems.

Efficient technical solution

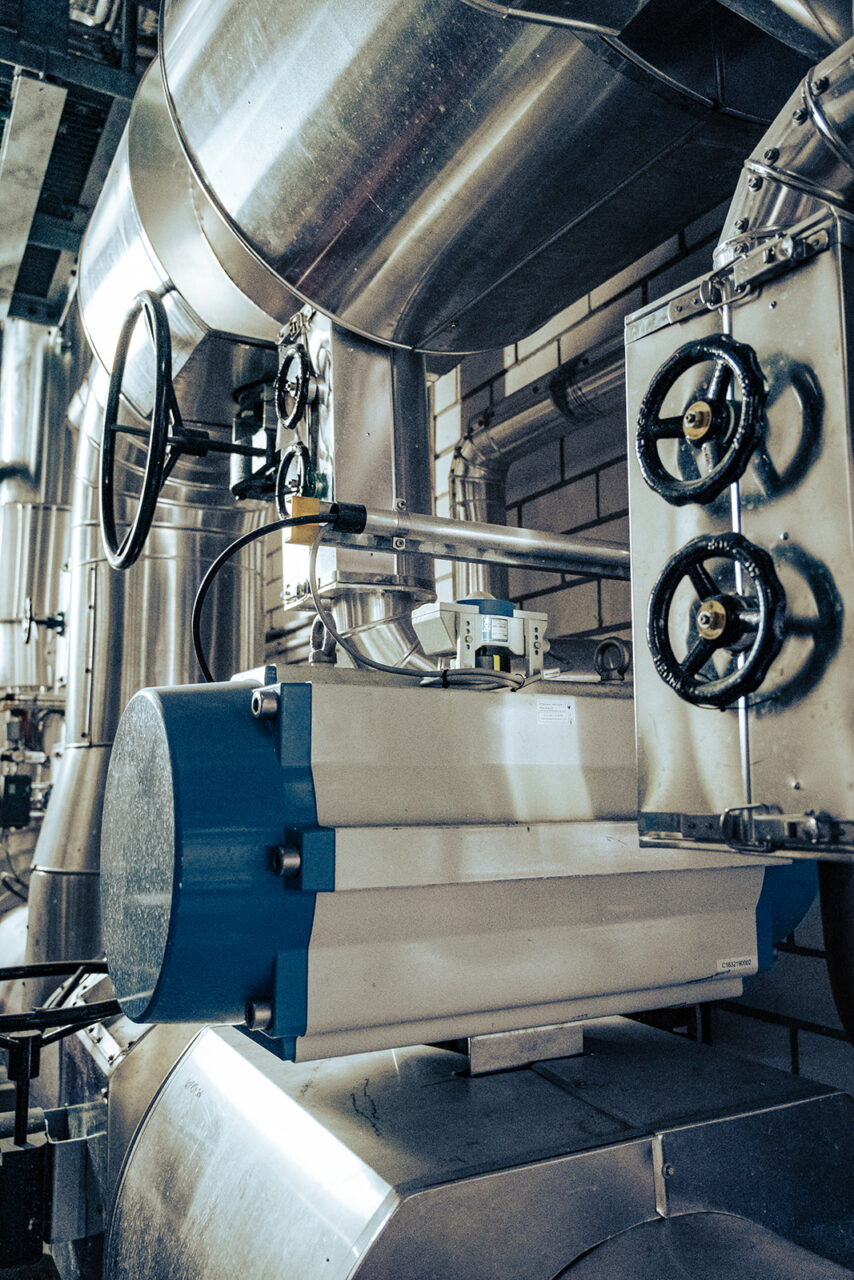

Two parallel DN300 forming stations

During the technical planning phase, it was initially possible to implement a DN600 forming station. However, it turned out that it would be difficult to efficiently regulate the minimum load case with such a station. For this reason, NOPA opted for an alternative solution: the use of two parallel DN300 forming stations. This decision had several advantages. Firstly, it made it possible to extend the control range, allowing more precise adaptation to different operating conditions. Secondly, this configuration led to a considerable reduction in delivery times. Another key advantage of this solution is the increased availability: both forming stations can be operated independently of each other, which significantly increases the flexibility and reliability of the system.

Result of the project at Hamburger Rieger

Successful commissioning and sustainable performance

The project at Hamburger Rieger GmbH Papierfabrik Spremberg was successfully implemented from July 2019 to February 2021. NOPA’s commitment resulted in precise and efficient plant equipment that enables a smooth operation. The successful commissioning was characterized by a strong partnership and technical expertise, with NOPA working closely with all parties involved – from clients to planning offices to technical service providers – to create a plant that meets the high requirements for operational reliability.